Electric Vehicle Testing Solutions from Unico

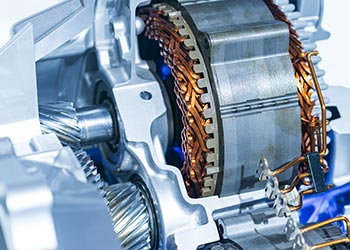

UNICO electric vehicle testing for EV batteries, E-Motors, E-Axle and EV propulsion systems include test stand systems for performance, validation and end of line testing.

Electric Vehicle Testing Systems from Unico.

UNICO electric vehicle testing systems make e-mobility and vehicle electrification development smooth and fast by offering the EV propulsion test stand systems you need, the technical expertise to spec your drives and controls systems, and global support for upgrades, service, and support. Your system is designed for the evolving needs of high voltage EV testing including performance, validation, and end of line testing.

UNICO systems are throughout the world in the best automotive testing facilities, within EV startup companies in aviation and delivery vehicles, at state-of-the art EV hypercar testing facilities, global testing centers of EV racing teams, and labs testing EV batteries, E-Motors, E-Axles and the EV propulsion systems.

The most diverse line of electric vehicle testing products.

Unico offers a comprehensive range of electric vehicle testing products exclusively designed for test stand applications. You can purchase an EV battery cycler, EV battery emulator, Universal Inverter, or E-Motor emulator separately – or as a modular drive system that combines a battery emulator, universal inverter, and E-Motor or E-Axle Dynamometer, all in a single package powered by a single active front end. This combination package saves floor space, reduces wiring complexity, simplifies installation, and saves energy.

These drives systems enable the production of numerous vehicles of different sizes and serve various purposes like R&D, validation, and certification.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The 7100 series is designed to meet the demands of testing cell-level batteries for existing and future generations....

EV Battery simulators / emulators for testing electric vehicle propulsion and powertrain systems, including traction...

Unico provides modular testing solutions with its Universal Inverter to test E-motors in EV applications. Find out more...

E-Motor emulators for testing electric vehicle traction inverters. Validate and test different inverter designs...

Our e-motor dyno drives allow you to verify the quality of your electric motors in a controlled, cost-saving, environment.

EV Battery cyclers for charge, discharge and lifecycle testing of EV battery packs and modules. High voltages and currents...

Our sales professionals are eagerly awaiting your questions. Fill out the form below and we’ll be in touch. If you’re looking for product support click here

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |